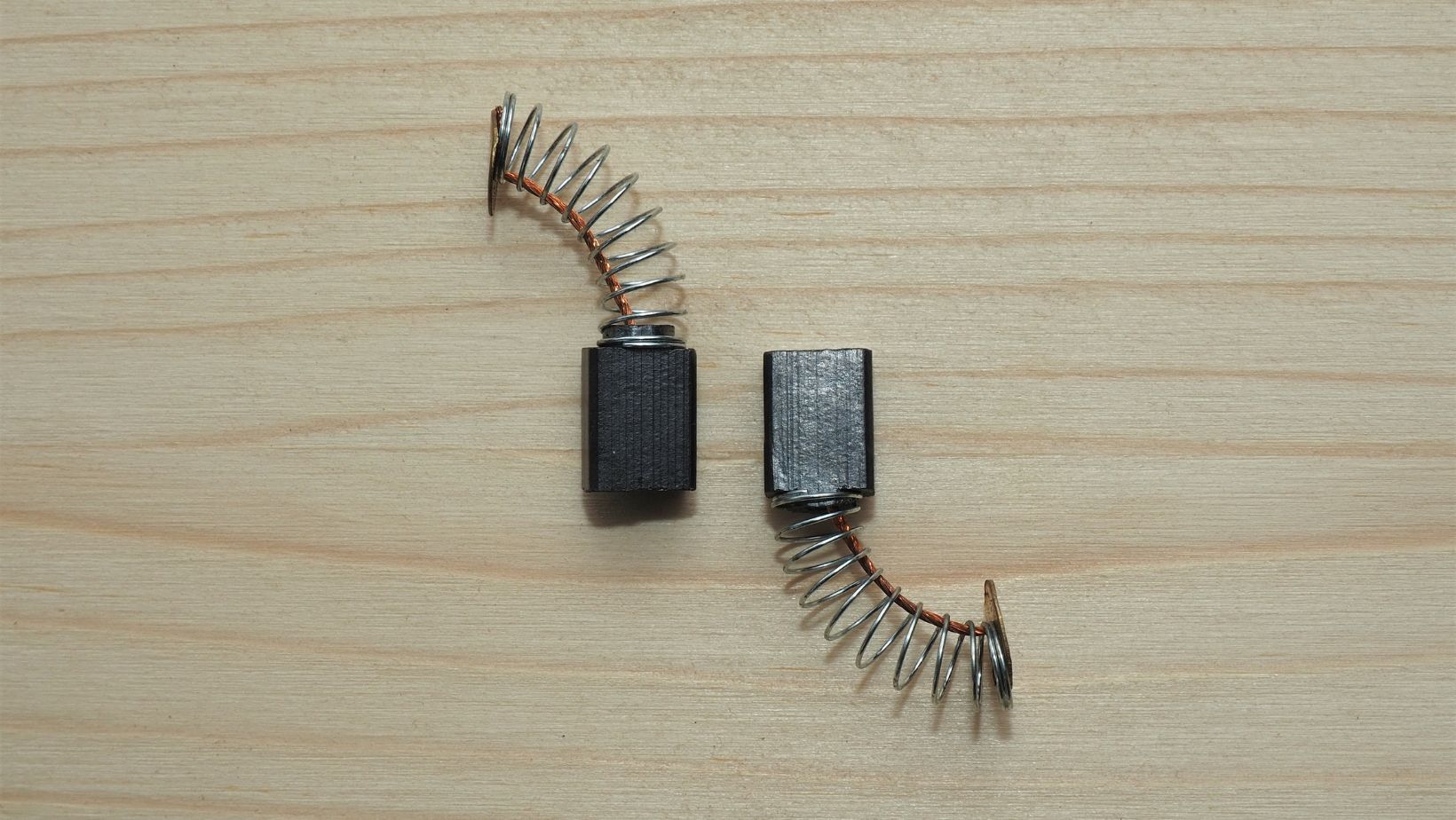

Power tools are indispensable in professional and DIY projects, but their efficiency hinges on the condition of their most minor components, like carbon brushes. These brushes, though minuscule, play a crucial role in the functionality of many power equipment. Over time, wear and tear on these components can lead to a decline in performance, unexpected downtime, and even costly repairs.

For enthusiasts and professionals alike, recognizing the right time to replace carbon brushes is essential to maintain the effectiveness and longevity of their tools. This article serves as a guide, outlining the critical indicators of wear and the steps to replace carbon brushes, ensuring gadgets remain in top working condition.

Where to Buy Carbon Brushes

Locating the right source for carbon brushes is crucial in ensuring that power tools continue operating efficiently. These essential components can be found in various places, catering to different needs and preferences. Top Deals Online is a reputable place to buy replacement carbon brushes, including generic brushes of various sizes and for loads of different brand.

- Hardware stores – Local hardware stores are often the first stop for many. They typically offer a selection of carbon brushes for standard power tool models. The advantage of buying from a hardware store is seeing the product firsthand and getting immediate assistance from knowledgeable staff.

- Online retailers – Online retailers are a go-to resource for a broader selection. E-commerce websites and specialized tool parts suppliers offer an extensive range of carbon brushes. The benefit of online shopping is the convenience and the ability to compare prices and feedbacks from different brands and dealers.

- Direct from manufacturers – Purchasing directly from the tool’s manufacturer is another option. They ensure that buyers receive the exact match for their tool model. Manufacturer websites or authorized dealers can provide genuine parts that guarantee compatibility and reliability.

- Specialty tool shop – They may be the best option for professional-grade and specific models. These shops often have a more in-depth knowledge of unique or high-end power tools and can offer particular carbon brushes that might not be available elsewhere.

- Local repair shops – Lastly, local repair shops sell carbon brushes and offer the added service of installation and advice on maintenance. This option can be particularly beneficial for those needing more confidence in replacing the parts.

When purchasing carbon brushes, it’s essential to know the exact model and specifications of the power tool to ensure compatibility. It’s also advisable to consider the supplier’s reputation and the brushes’ quality, as these factors directly impact the tool’s performance and lifespan.

Understanding Carbon Brushes

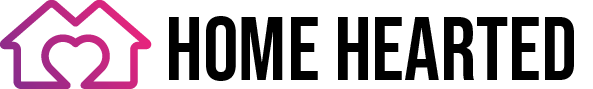

Carbon brushes are a fundamental component in many power apparatus, acting as a conduit for electrical current between stationary and moving parts. Typically made from carbon or graphite, these brushes maintain contact with the motor’s rotating part, known as the commutator. This contact allows for the transfer of electricity, powering the mechanism while enabling it to turn smoothly.

The performance of carbon brushes is vital to maintaining the efficiency of power tools. These components naturally wear down due to friction, necessitating regular replacement to sustain the tool’s optimal functionality.

Understanding the role of carbon brushes and the materials they’re composed of is critical in determining the right time for their replacement. Also, properly storing power tools can significantly prolong the lifespan of carbon brushes and devices, safeguarding their functionality and efficiency over time.

Factors Affecting Carbon Brush Lifespan

The lifespan of carbon brushes in power tools can vary widely, influenced by several key factors:

- Frequency of use – Regular and intensive use of power tools naturally accelerate the wear of carbon brushes. Tools used daily or for heavy-duty tasks require more frequent brush replacements.

- Type of tool and motor – Different tools and motor types exert varying stress levels on carbon brushes. High-power tools, for instance, often wear down brushes quicker than those operating at lower power levels.

- Quality of brushes – Carbon brushes’ material composition and manufacturing quality play a significant role. Higher-quality brushes usually offer a longer service life.

- Operating conditions: Harsh operating environments, such as those with dust, moisture, or extreme temperatures, can lead to quicker degradation of carbon brushes.

- Maintenance practices – Proper tool maintenance, including regular cleaning and inspection, can prolong the life of carbon brushes. Neglecting maintenance often leads to premature wear.

Understanding these factors can help users anticipate when their power tool’s carbon brushes might need replacement and take proactive steps to maximize their lifespan.

Signs of Carbon Brush Wear

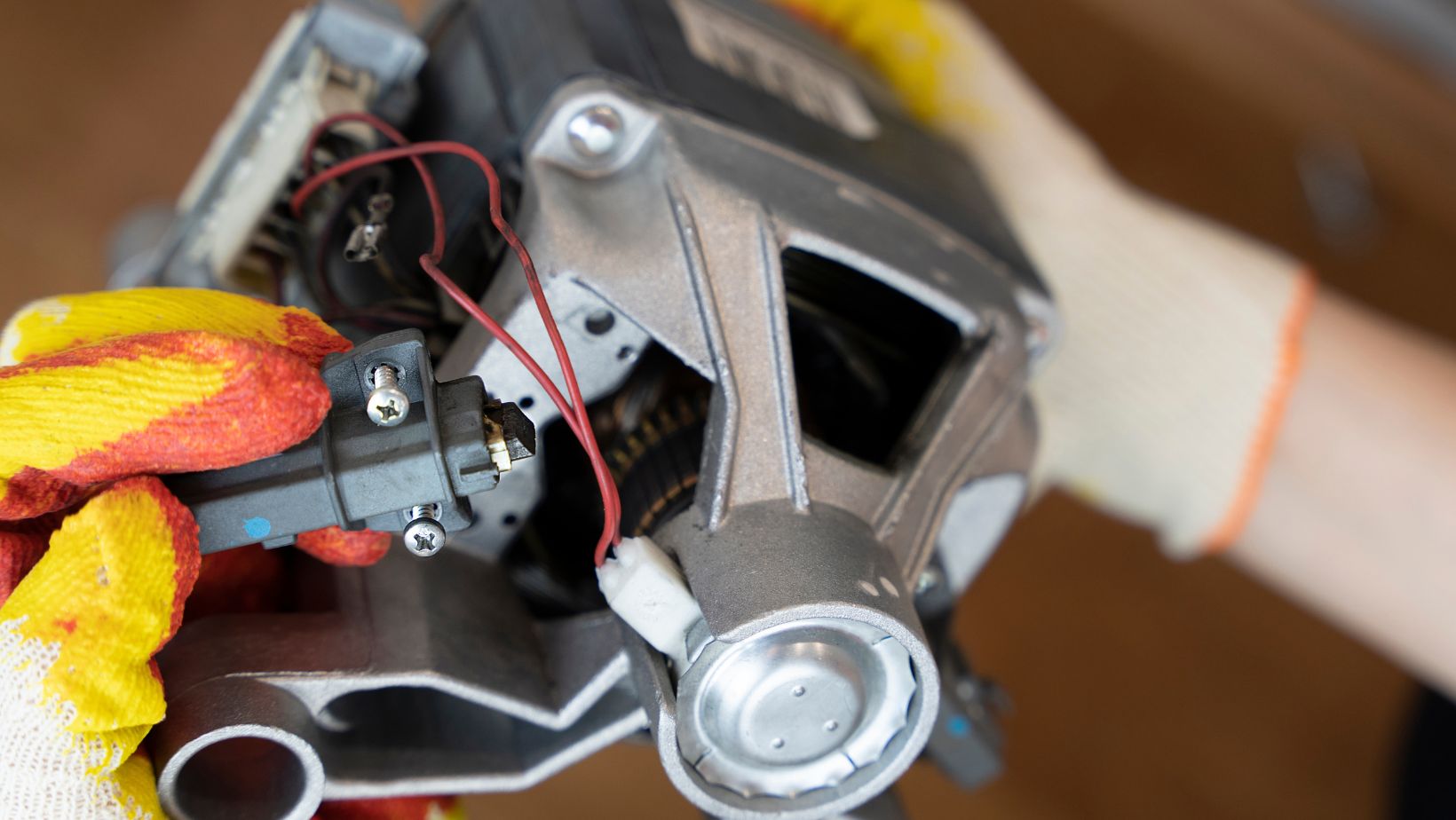

Identifying wear in carbon brushes is key to maintaining power tool efficiency. Several signs indicate it’s time to inspect and possibly replace them:

- Decreased tool performance – A noticeable decline in the power tool’s performance, such as reduced speed or inconsistency in operation, often signals worn brushes.

- Sparking from the tool – Excessive sparking from the area where the brushes contact the motor is a common sign of wear. While minimal sparking is normal, increased spark production indicates that the parts are no longer making proper contact.

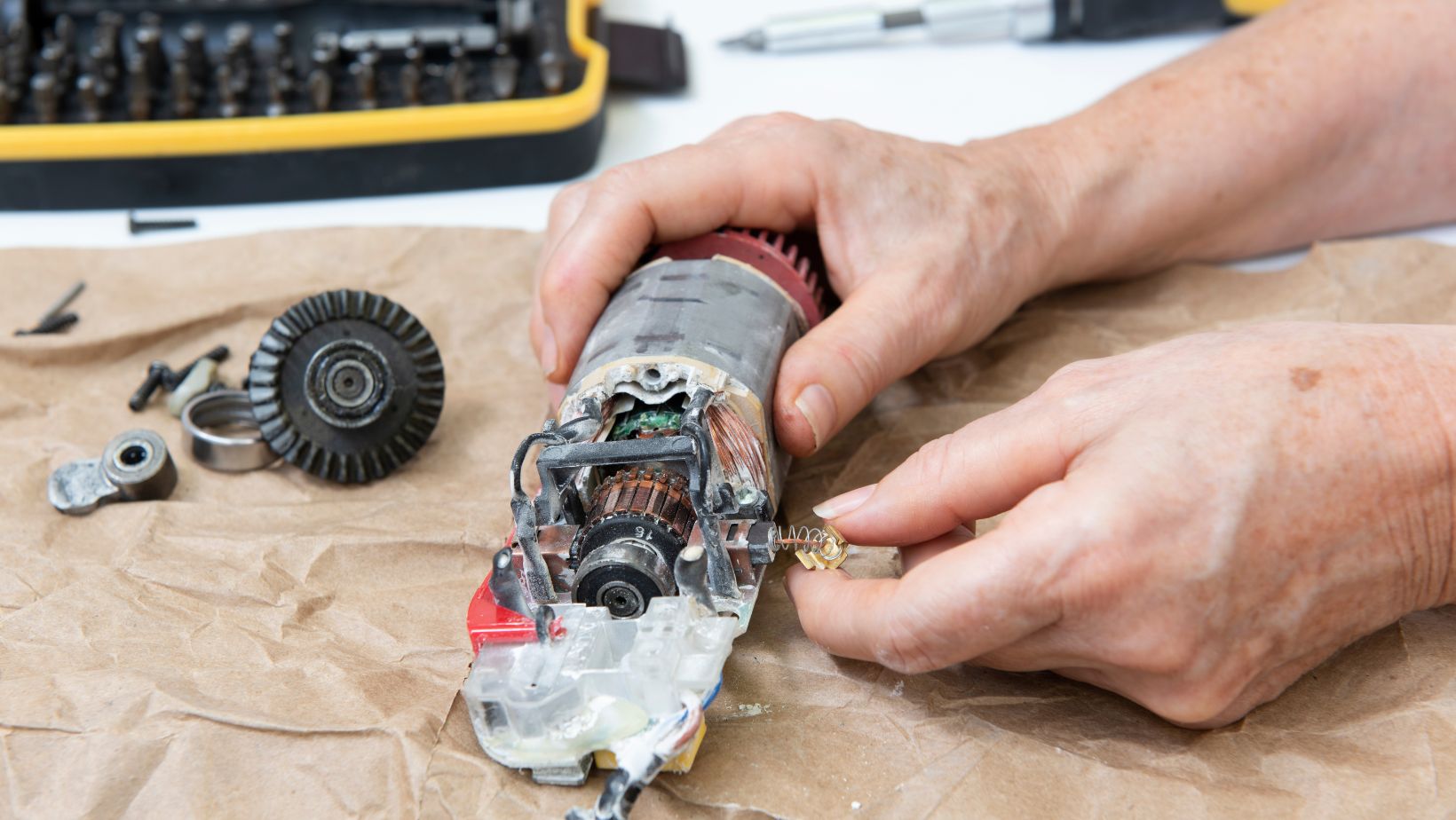

- Physical wear – Visual inspection can significantly reveal wear on the brushes. If the brushes have notably shortened, show uneven wear, or are chipped, this indicates a need for replacement.

- Unusual noises – Grinding or unusual sounds from the motor area can indicate that the brushes are worn out and are no longer making smooth contact with the commutator.

- Difficulty starting: If the tool struggles to start or requires multiple attempts, worn brushes could be the culprit, as they may not conduct electricity effectively.

Regularly checking for these signs and replacing the carbon brushes, when necessary, can prevent further damage to the power tool and ensure its longevity and excellent performance.

Conclusion

Knowing when to replace carbon brushes is critical to keeping your power tools in prime condition. Stay vigilant for wear signs and understand what affects their lifespan for timely replacement. Regular checks of your power tools and swift action in replacing worn brushes are crucial.

These steps boost the efficiency of your gadgets and extend their lifespan. Use this as a prompt to inspect them and replace brushes as needed, ensuring they’re always ready for optimal performance in your projects.