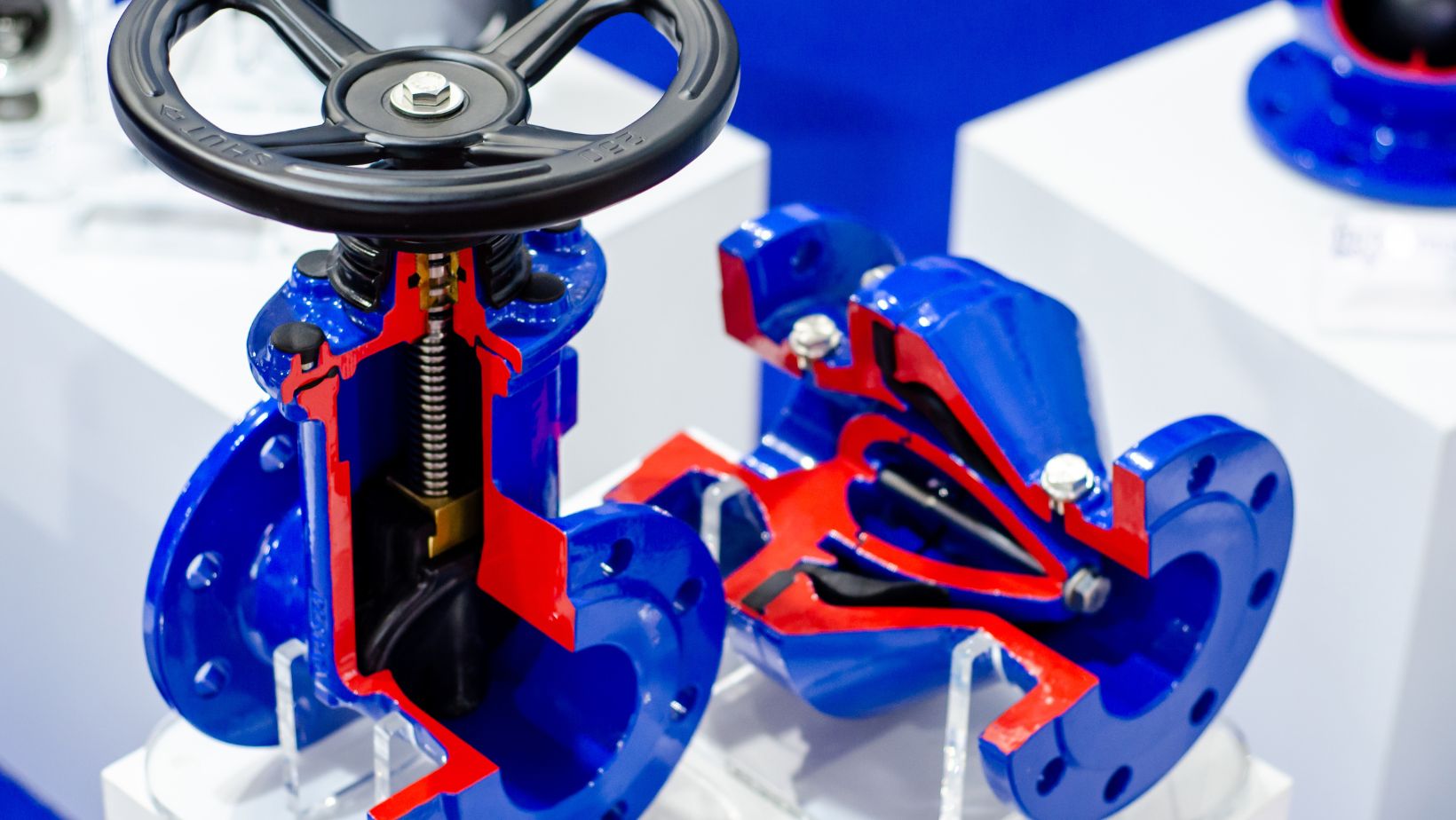

In HVAC systems, globe valves are absolutely crucial since they guarantee exact control over gas and liquid movement. Within heating, ventilation, and air conditioning systems, these vital parts provide safety, performance, and efficiency. Globe valves need correct maintenance to guarantee long-term operation, just as any mechanical component.

Effective maintenance plans help you to increase the lifetime of these valves, saving money and preventing operational downtime. Therefore, this article will outline some of the maintenance ideas that will help you keep your globe valves running as best they should.

Regular Inspection

Identifying issues with the valve in your HVAC before they get out of hand depends on regular inspections. Look for obvious wear during inspections, such as corrosion, leaks, or valve body damage. Focus especially on the bonnet, stem, and seat since these are most likely to deteriorate. This will help you identify profound issues before they demand a full repair.

Working on complex components like the UGVL+SVKB24-SR, check the electronic actuators and connections for any indications of dysfunction. Frequent inspections provide quick resolution of any problems, reducing the possibility of expensive repairs. Therefore, you will save yourself a lot of money.

Lubricate the Moving Parts

Maintaining perfect valve operation depends on proper lubrication. Periodically, lubrication of the stem and other moving components of the valve helps to lower friction and wear. Still, it’s crucial to use the kind of lubrication the valve manufacturer suggests. Lubrication should be done frequently to ensure the valve condition improves over time.

Using the incorrect lubricant or over-lubrication might draw dust and dirt, therefore sometimes inflicting more damage than benefit. A balanced method guarantees the valve runs effectively free from pointless resistance.

Understand its Roles

Knowing the particular use of your globe valves in your HVAC system will help you approach maintenance. Many times, utilized for throttling purposes, globe valves allow exact flow control. In situations where accuracy and dependability rule, are very useful.

Knowing their importance helps you pinpoint the most critical maintenance routines. Valves regulating hot water systems, for instance, could show wear patterns distinct from those of air handlers. For this reason, understanding its roles is essential since it can allow you to know how it develops.

Maintain Cleanliness

Your valves’ lifetime and performance may be compromised by debris and silt. HVAC systems attract and retain a lot of dirt, which can become a problem when accumulated for a long time. As particles in the fluid buildup over time, the valve may become blocked or eroded. Install filters to reduce the entrance of pollutants and routinely flush the system to help prevent this.

Apart from safeguarding the valve, a clean system increases the general effectiveness of your HVAC arrangement. Older systems that could produce more waste especially depend on regular flushing and filter maintenance. You need to schedule regular cleaning practices to ensure the valve is kept in perfect condition.

Monitor Operating Conditions

Designed to operate within designated temperature and pressure limits, globe valves Beyond these limits, the lifetime of the valve can be considerably reduced. To make sure your HVAC system stays within the designated limitations, routinely check its running conditions.

Modern valves have sophisticated capabilities meant to track performance and offer feedback. By tracking running conditions in real-time and making necessary adjustments using such instruments, you can safeguard the valve. Hence, it will be easier for your valve to last longer if you understand the condition, it is in.

Test its Performance

Regular functioning checks enable one to confirm that the globe valve is running as it should. To look for any movement or resistance, open and close the valve. Listen for odd noises, such as grinding or squeaking, which can point to internal wear or misalignment.

Furthermore, guaranteeing correct flow control is a crucial component for preserving HVAC efficiency. Functional testing guarantees the valve is working properly. Should problems arise, take quick care of them to avoid more complications.

Replace Worn Components

Your globe valves will eventually wear out regardless of how carefully you maintain them. Parts, including the seat, gaskets, and stem packing, are particularly sensitive to wear. Replacing these components early on helps to stop more significant valve assembly damage.

Always replace parts recommended by manufacturers to guarantee dependability and fit. This is particularly crucial for complex systems using specialist components like the UGVL+SVKB24-SR, where compatibility and accuracy are vital.

Document Maintenance Activities

Maintaining a thorough record of maintenance operations facilitates your tracking of the valve’s performance and condition over time. Record every inspection, repair, and replacement, including the date, results, and activities done.

By offering insightful analysis of wear trends, maintenance records enable you to plan preventative maintenance and project future needs. In the long term, this proactive strategy can save you money and time.

Proper Handling

One often occurring cause of valve damage is human mistakes. Unneeded wear and tear results from improper handling during installation, operation, or maintenance. Your staff must be taught the proper techniques for handling and running globe valves.

Encouragement of a culture of care and attention will help to reduce the possibility of inadvertent harm and guarantee that your valves are handled with the dignity they so merit.

Schedule Professional Maintenance

Although routine internal maintenance is vital, scheduling expert visits and servicing can offer still another degree of confidence. Certified technicians can offer customized solutions to maintain the top condition of your globe valves and possess the knowledge to spot problems that could otherwise go overlooked.

For complex HVAC systems where sophisticated diagnostics tools and specialist knowledge may be needed, professional maintenance is essential.

The lifetime and effectiveness of your HVAC system depend on valves being properly maintained. From routine inspections and lubrication to advanced monitoring and professional servicing, every action helps to maintain these critical parts in the best shape. These guidelines will help you to guarantee constant functioning and increase the lifetime of your globe valves.

Whether you run a conventional system or use cutting-edge technologies, proactive valve care will pay off in terms of lower downtime and better system efficiency. Give regular maintenance priority, and provide your staff with the tools they need to keep a dependable and reasonably priced HVAC system.